On an experimental farm at the University of Florida’s Southwest Florida Research and Education Center, the fourth revolution of agriculture is under way.

Drones fly over citrus groves, counting and categorizing trees.

Robotic arms collect pests from tree branches to determine which trees need to be treated.

Imagers collect data from tomato plants about diseases like target spot and bacterial spot before they spread throughout a field.

Remote sensing equipment scours groves, up one row and down the next, to survey for green versus ripe fruit.

Machines straddle rows of peppers, sensors spotting and spraying weeds only as they encounter them.

And, behind the scenes, a cloud-based software called Agroview sucks up all the data, analyzing and synthesizing it into chunks that scientists — and farmers — can use to make better decisions.

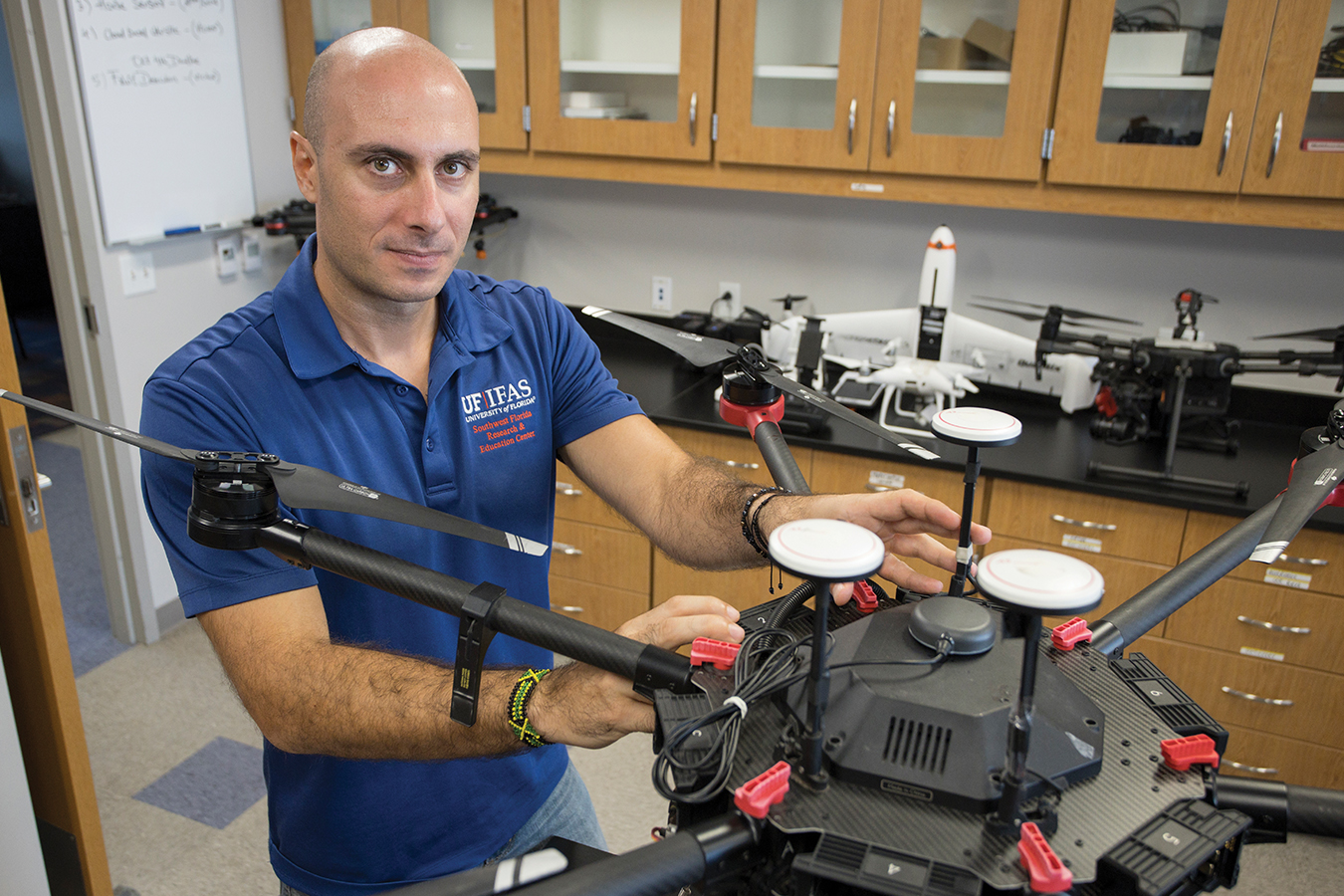

Yiannis Ampatzidis says artificial intelligence is changing the face of agriculture in a way that is nothing short of revolutionary.

“Artificial intelligence, robotics, automation, big data analytics, the internet of things. This is no doubt the fourth agricultural revolution,”

– Yiannis Ampatzidis, Associate professor in UF’s Institute of Food and Agricultural Sciences

Yiannis Ampatzidis

“We are going to see these technologies in the field very, very soon.”

In the first agricultural revolution, mechanization — tractors, harvesters and such — changed life on the farm. In the second, chemicals — fertilizers and pesticides —dramatically increased yields. In the third, genetics produced hybrid plants, boosting yields yet again. What will artificial intelligence capabilities do for agriculture in the fourth revolution? A better question, Ampatzidis says, is what won’t they do?

Ampatzidis — whose research is funded by the U.S. Department of Agriculture, the Florida Department of Agriculture and Consumer Services, and private industry — says automating even basic tasks pays off, especially for citrus, Florida’s signature crop. For example, just creating a tree inventory for a grove is expensive and time-consuming.

“Before automation, an inventory required driving throughout a field with two people, one looking left, one looking right. They would each have counting devices or clickers, and if they see a big tree they click one clicker, and if they see a small tree they click another one,” Ampatzidis says.

Manually counting trees on just 1,000 acres could cost up to $14 an acre. Using drones, the time can be reduced by 90 percent and the cost by 60 to 70 percent, Ampatzidis says.

And once the drone images are uploaded into Agroview, the grower can access much more than just a tree count. Agroview processes and analyzes the visual images to provide information such as tree height, canopy size, stress conditions and gaps where trees need to be replanted.

A ground-based system can be paired with Agroview to detect and count fruit, even immature green fruit, which is difficult because green fruit is the same color as the leaves. This helps the grower monitor growth, predict yield and prepare for harvests.

J. Scott Angle, UF’s senior vice president for agriculture and natural resources, says AI will leverage the capabilities of other technologies. For example, mechanization has been around a long time, waiting for the technologies that will make machines smarter. And smart mechanization will become even more important in the face of labor shortages, he says.

“We’ve always had the mechanical part, let’s say, for picking a peach,” Angle says. “We’ve got claws that can reach out, grab it, pull it off the branch, throw it into a bin. The problem is, is that peach ripe, ready to be picked? That’s a hard question.

“A human can determine that easily, but a robot can’t. Secondly, when you grab that peach, if it’s ripe and you put too much pressure on it, you’ll squish it. And if you don’t apply enough pressure, it’ll drop out of the claw.”

“So that’s a question for AI to solve for us. Every peach will become a specific calculation,” Angle says. “I think in the next couple of years, we’re going to see robots in our orchards and our groves harvesting a lot of our crops.”

In Florida’s fields of tomatoes — the state’s third-largest crop — drones are the newest workhorses.

Using imagers far more sophisticated than inspection by the human eye, drones outfitted with cameras can measure reflected solar radiation to detect diseases like the two scourges of tomatoes — bacterial spot and target spot — with around 90% accuracy. The diseases cost Florida tomato farmers about $5 million a year.

In a 20-minute flight, the drones can scan about 60 acres of tomato fields, a huge time savings for growers, who otherwise would manually have to check for the diseases row by row.

The system also detects disease at a very early stage, which is critical for growers, and can distinguish between bacterial spot and target spot, so the right chemical — and the right amount of chemical — can be used. Based on the data gathered, Ampatzidis says the team also has developed AI models to predict diseases in other vegetable crops as well as tomatoes.

Another technology is being tested on peppers. Ampatzidis calls it a smart sprayer because the apparatus travels above a row and, using machine vision and AI, sprays herbicide when it spots a weed. It doesn’t spray when it spots non-target plants, like the peppers themselves or sedgegrass. The smart sprayer saves both money and chemicals, helping the farmers and the consumers who buy the produce.

UF agricultural engineers are also working on an autonomous robotic harvester of strawberries, a crop with such severe labor issues that some growers have considered not planting as opposed to planting and letting unpicked crops rot in the fields.

In row crops, Agroview can show spacing and overlay data about where pests have been detected, allowing it to create a “prescription map” with detailed instructions on where to apply fertilizers and pesticides to best effect.

Prescription mapping and smart sprayers are not only good for growers’ budgets, they are good for the environment, too, because reducing pesticides and fertilizers means less chemicals seeping into Florida water supplies.

“Every tree, every vegetable plant will have its own name. For the first time ever, we will be able to treat in a way that the tree utilizes every nutrient, and that means less runoff into water supplies,” says Todd Motis, a manager at Chemical Containers, an agricultural equipment designer and manufacturer. “Cost savings may drive sales, but the best reason to do this is to protect our water.”

USDA Research Impact

Direct Economic Contributions of Florida Agriculture (2022)